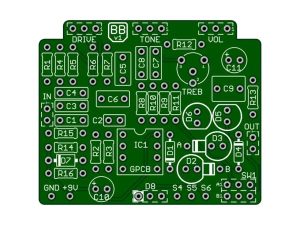

PCB stands for “printed circuit board,” and that’s pretty much what it is. Using special printers, all connections needed between components are created and the holes needed or each component are also put in place. In this way, all that’s needed to build a guitar pedal (or whatever you’re making) is to populate the PCB with the relevant components.

PCB stands for “printed circuit board,” and that’s pretty much what it is. Using special printers, all connections needed between components are created and the holes needed or each component are also put in place. In this way, all that’s needed to build a guitar pedal (or whatever you’re making) is to populate the PCB with the relevant components.

All the component locations are labeled by number, so it’s just a matter of placing the components in the right place. You may see labels such as “R1” for resistor one and “C3” for capacitor three.

A lot of the time, you can buy guitar pedal kits that come with a PCB, all the components that you need, and instructions on which components go where.

A guitar pedal PCB kit can be an excellent way to get into the hobby. With a PCB kit, all the components you need are taken care of for you and it’s just a matter of soldering the right component into the right place. It’s a lot like Lego, but just with electronic components and a soldering iron that can melt skin!

The Advantages Of Using PCBs To Build Guitar Pedals

There are two main advantages to using PCBs to build guitar pedals.

The first advantage is for beginners. PCB guitar pedal kits present easy to follow directions that give beginners and newbies an accessible way to get into the hobby of making guitar pedals. While it’s almost just as simple to follow a stripboard layout, soldering PCBs it’s a lot easier and it’s a lot less likely that you’ll put a component in the wrong place.

For more advanced pedal builders, a PCB offers a faster way to manufacture guitar pedals by hand. As with beginners using PCBs, an experienced pedal builder just needs to solder the right component in place and be done with it. This is faster than using stripboard because stripboard needs to be cut to size, have cuts and connections made, and then the layout needs to be followed rather than just “put R5 in the whole marked R5.” For people who pride themselves on making hand made guitar pedals, but want to make them at volume, a PCB really speeds things up.

And that’s where the main reason to use PCBs comes into play: you can get a bunch of the same PCB printed up and then make a bunch of the same thing quite quickly.

Going further, since PCBs can be printed with multiple layers to them, it’s usually the case that a PCB is a lot smaller than the stripboard layout for the same pedal. That’s to say that on stripboard, the only conductive layer is at the bottom side of the board. For PCBs, there may be conductive layers throughout the board, saving on overall space.

Finally, assuming you have a PCB layout that you know is working, if the guitar pedal isn’t working once the PCB is populated, it’s a lot easier to diagnose the issue.

The Disadvantages Of Using PCBs To Build Guitar Pedals

I’m going to preface this section by saying that personally, I prefer stripboard. Maybe I’ll one day get to the point where I design a really cool guitar pedal circuit and have enough demand to make multiple pedals quickly, so I’d need to get PCBs made. But, if I’m making a clone or making a modification to a pedal circuit that I like, I prefer stripboard. So take this section with a grain of salt because I do have some bias.

Personally, I think that the biggest drawback to staying with PCBs, especially as a hobbyist, is that it limits what you can make. Websites like Tagboard Effects have literally thousands of stripboard layouts for almost any guitar pedal you can think of. Pedal kit manufacturers obviously only concentrate on the most popular pedals because that’s what’s going to sell. Staying with PCB only builds, you limit yourself. At least as a hobbyist…

With that, using a PCB to build a guitar pedal limits modifications. While you can substitute components, you can’t add them. So if you want to add a switch, or add a tone filter, or something like that, you can’t if you order a PCB kit.

Sure, as mentioned, if you’ve developed a cool pedal circuit and you want to make it permanent, a PCB is the way to go. But, while you’re fiddling around and making prototypes, those prototypes will likely be built on stripboard.

Enjoying This Component Guide?

Learn more about PCBs and other guitar pedal components.

Finding Good Guitar Pedal PCB Kits

If you’re new to guitar pedal building, or just prefer using PCBs, there are a myriad of kits out there online. I’m not going to suggest a particular one because different places have different shipping.

Some things you’ll want to consider when choosing a guitar pedal kit include:

- The manufacturer/distributer is reputable: personally, I’ve noticed a lot of online electronics distributors don’t have the best websites, but they do get reviews; check them out.

- Confirm whether you’re buying a full kits that includes the PCB and all the components or just the PCB. If it’s just the PCB, it should also have a list of the components you need. You can usually buy these from the same distributor, but not always.

- Confirm that the kit comes with an enclosure. Not all kits come with an enclosure, so double check this. If this is your first pedal, consider buying a slightly larger enclosure to make it easier.

- Don’t jump in too deep: there are kits with dozen of components on them, and this shouldn’t be your first kit. Choose something with fewer components. I have a list of good beginner guitar pedal builds; most of these are great stripboard builds, but you may be able to find PCBs of them too.

Making Your Own PCBs

If you do have a circuit that you like and you plan to make multiple copies of it, it’s possible to get your own PCBs made. How to design a PCB and get it printed is for another post, but I have had a try of it. I tried, and failed, because I didn’t know what I was doing and jumped into something way too complex for my skill level, but it was quite fun! It’s something I’d like to try to do again, but for now my guitar pedal interests revolve around pouring my knowledge into this blog and learning more through making and modifying clones (on stripboard!).

If you are interested in getting your own PCBs made, there are computer programs available that can help you design them. From there, they’re not too expensive, usually less than a dollar per board; although you usually need to order at least 10 and shipping can be a pain. Learn from my mistake: start with something simple!

Get Out There And Build

Although I admittedly prefer stripboard, PCB guitar pedal kits can be a great way to get into pedal building. If you’re more experienced, getting some PCBs printed so you can start manufacturing pedals can also be a lot of fun.

So, if building guitar pedals on PCBs sounds like your thing, get out there and build something!

Related posts:

Should I Make Guitar Pedals On Stripboard Or PCBs?

Should I Make Guitar Pedals On Stripboard Or PCBs?

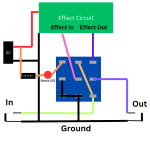

How To Wire A Guitar Pedal Foot Switch (3PDT)

How To Wire A Guitar Pedal Foot Switch (3PDT)

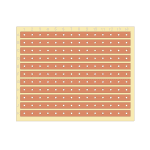

What Is Stripboard And How Do You Read Layouts?

What Is Stripboard And How Do You Read Layouts?

How To Wire A Guitar Pedal DC Power Jack

How To Wire A Guitar Pedal DC Power Jack

How To Wire Guitar Pedal Enclosures

How To Wire Guitar Pedal Enclosures

What Is True Bypass In Guitar Pedals?

What Is True Bypass In Guitar Pedals?

How Do Guitar Pedal (And Guitar) Volume Knobs Work?

How Do Guitar Pedal (And Guitar) Volume Knobs Work?

How Does A Drive, Gain, Or Distortion Knob Work?

How Does A Drive, Gain, Or Distortion Knob Work?

Ultimate Guide To Capacitors In Guitar Pedals: What They Do And How They Work

Ultimate Guide To Capacitors In Guitar Pedals: What They Do And How They Work

How To Use A Distortion Or Overdrive Pedal

How To Use A Distortion Or Overdrive Pedal